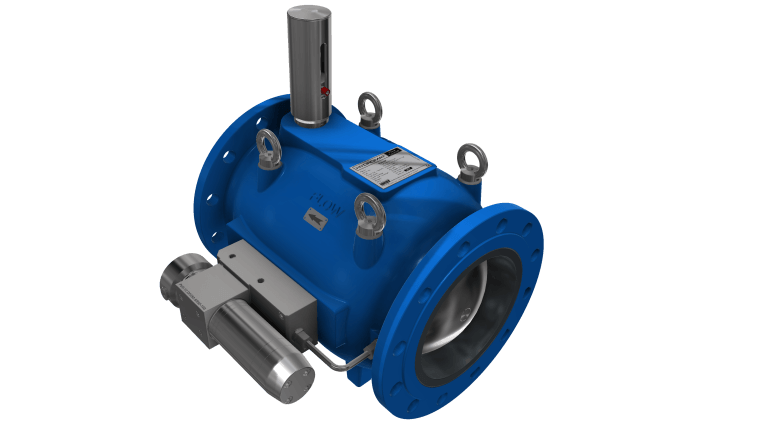

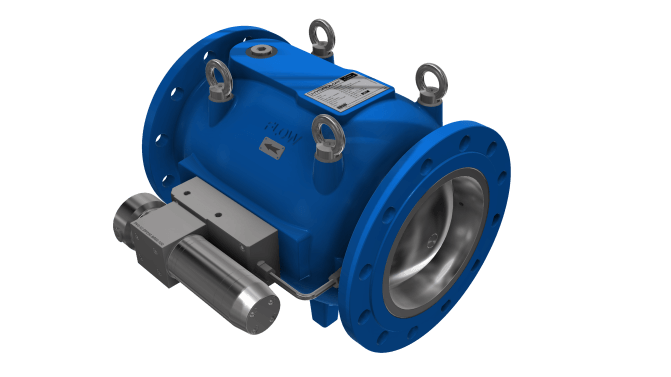

AXIAL CHECK VALVE – ADVANCED TYPE

ADVANCED AXIAL CHECK VALVE – COST EFFECTIVE AND EXTREMELY RELIABLE SOLUTIONS

Extremely reliable solution in pump and facility protection for intensive back pressure or water hammer, because it allows use of the massive force of spring or accumulator pressure. As we know in all classic solutions, the spring must be aligned with flow conditions which can be sometimes very impractical. HYREVAL® advanced solution allows automatically full opening with a very strong spring at pump pressure > 2 bar regardless of steady flow velocity, which means complete elimination of flow losses arising from spring or accumulator action. This concept is extremely beneficial in usage of water (potable, process, raw), compressed air, oil and gas…

Fully closing is currently achieved at the moment when the pump is stopped regardless of reverse flow velocity, which means extremely fast closing. This concept is extremely advantageous for use on water (potable, process, raw), compressed air, oil and gas…

ADVANCED TYPE

Equipped with pilot valve and feedback for the openness control

ADVANCED TYPE

Equipped with pilot valve and can be equipped with openess control feedback

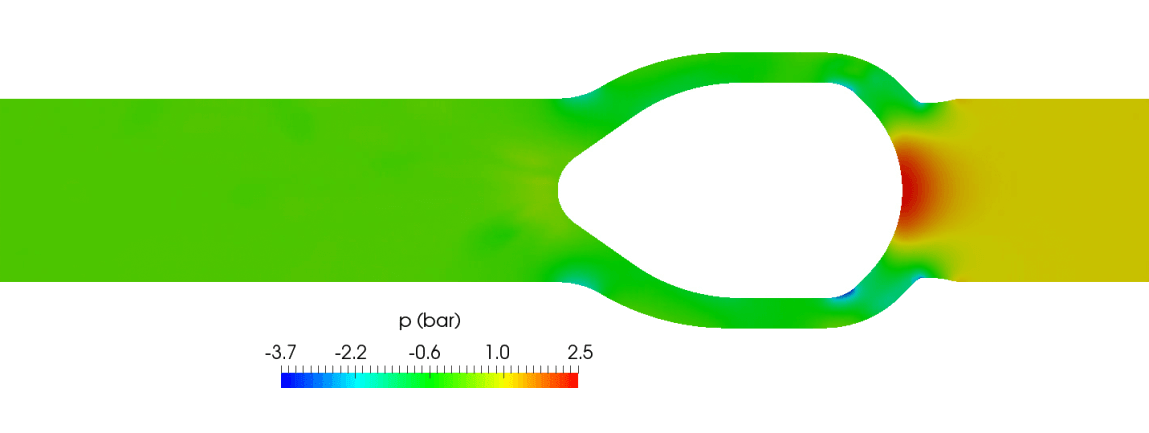

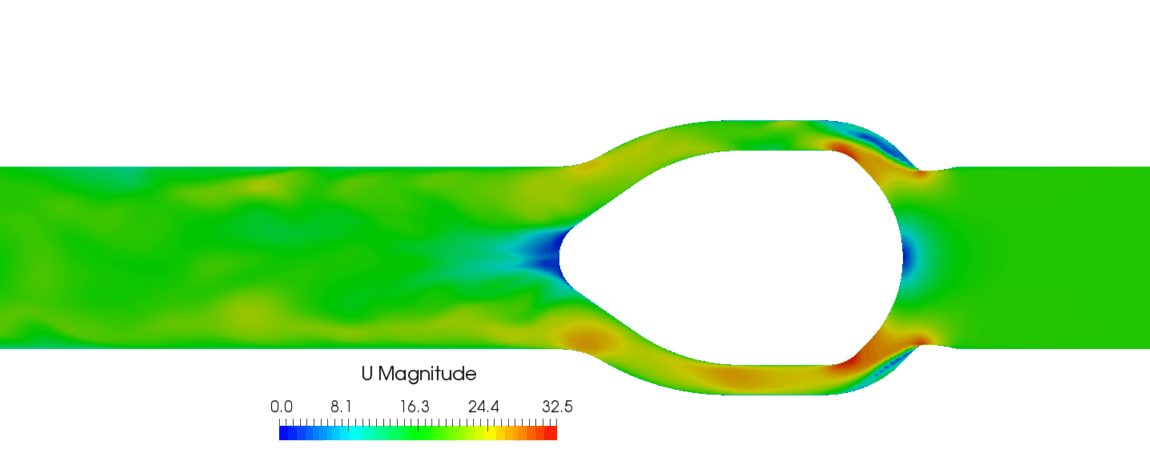

Extremely good and natural hydrodynamic flow profile provides minimum flow losses and minimal cavitation damages.

CV.ADS

Operating with pilot valve. Design with a strong spring for extremly fast closing direction.

Adjustable closing and opening time.

End position damping avoids hard impact of the disk on valve seat.

Fully closed position achieved at the moment when the pump is stopped regardless reverse flow velocity.

Possible remote control add operating.

CV.ADA

Operating with pilot valve. Design with accumulator.

Provides different strong closing force by variable accumulator pressure.

Excellent „response characteristic” of the check valve according to real flow conditions at the installation site.

End position damping.

Possible connection for additional operating pressure

CV.EXOP

Flexible design w/wo strong spring

Enables connection for compressed air or other fluids for necessary closing and/or opening force.

Since the flow medium does not have a direct contact with the disc guides ,thus meaning a much longer service life of the check valve and in the contaminated flow media.

Possible closing time less than 0,1 second.

Possible remote control add operating.