AUTOMATIZED SHOCK ABSORBER UNITS AND COMBINED PROPERTIES OF CHECK VALVES

Check valves with disc and flaps equipped with different types of automatized hydraulic damping units.

Combined properties of check valves

The automatic free-acting of hydraulic damping system ensures extremely reliable protection.

In addition to hydraulic damping in the closing direction, these systems have flow control capability in the sense of taking any disc position hydraullically, which includes check valves throttling position, tight shut-off position and holding full-open position.

These are the main charactersitics of combined check valves.

With that knowledge in mind, hydromat offers three solutions of automatized hydraulic shock absorber units with general features:

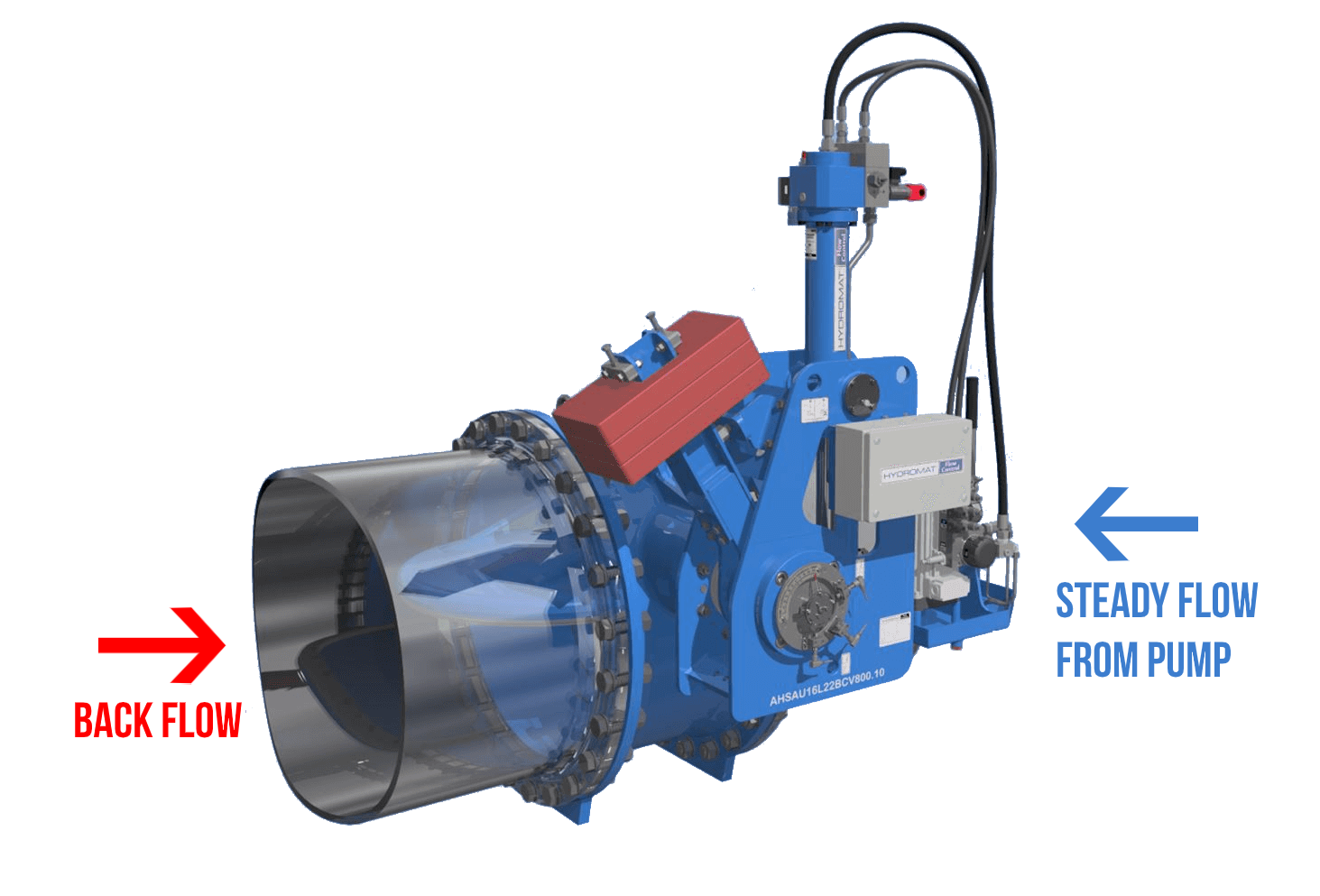

HYDRAULIC – type HA.HSAU

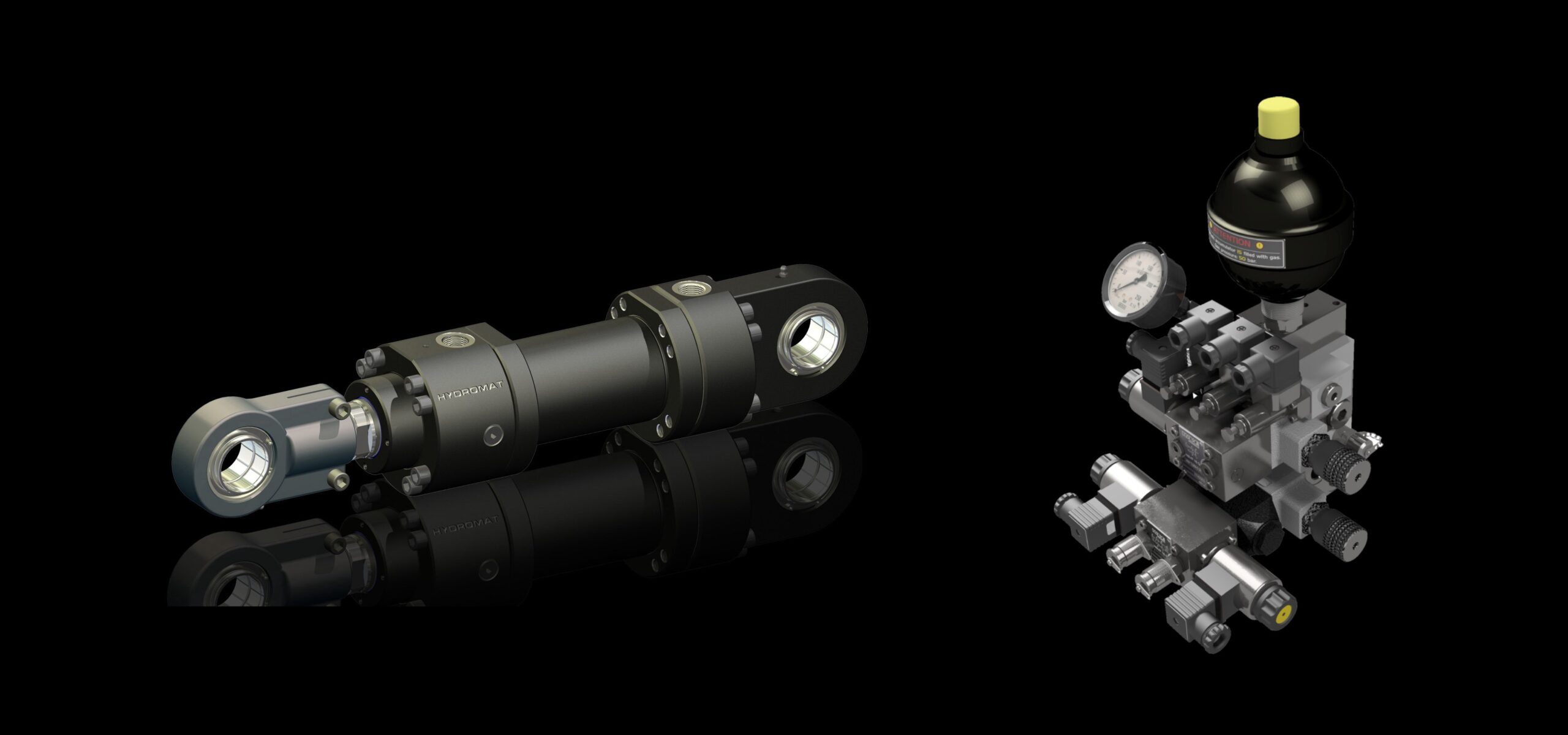

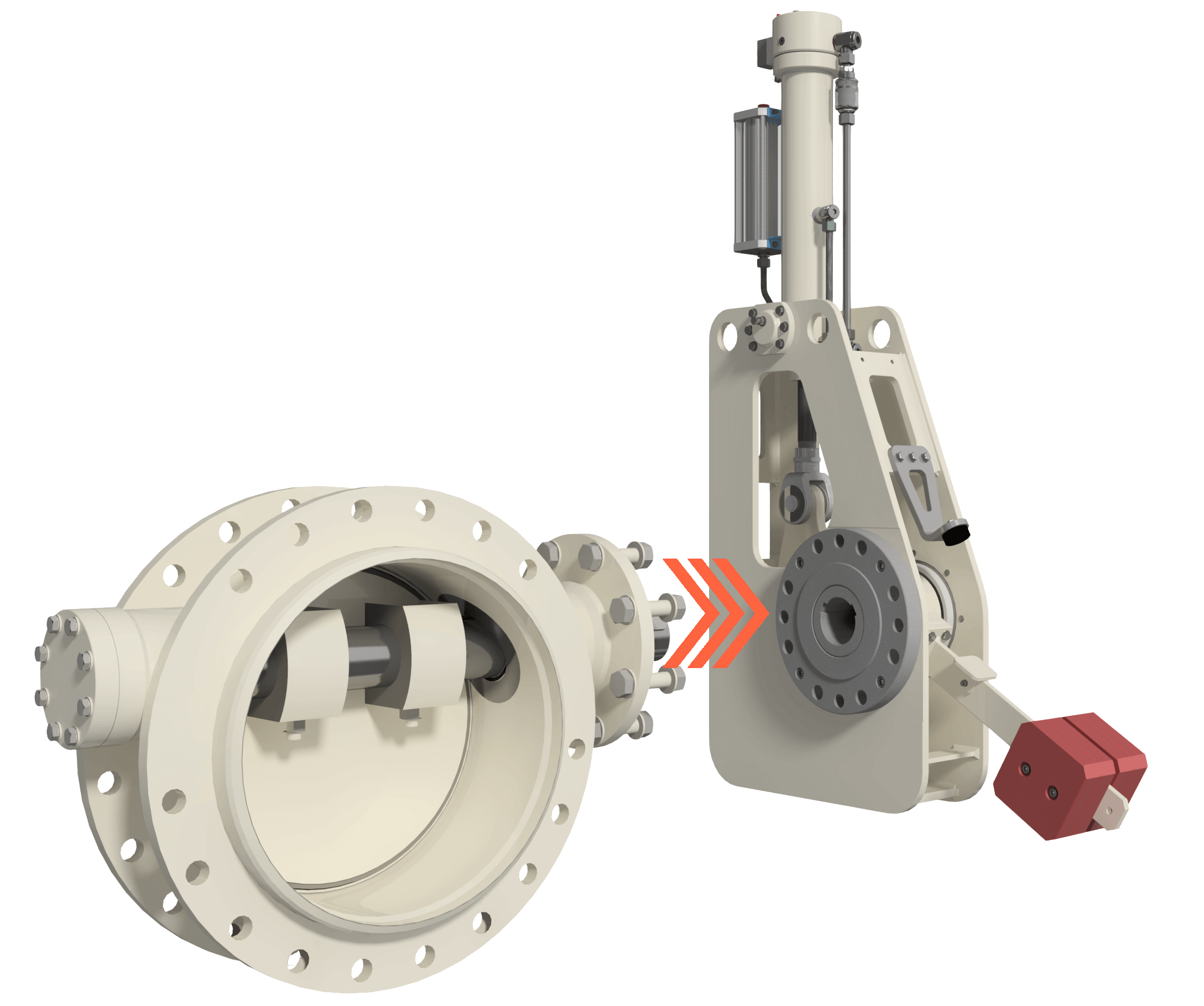

One compact unit is integrated with a hydraulic shock absorber and hydraulic cylinder for all the check valve functions which is connected with an hydraulic power unit placed directly on the check valve, or at distance.

HYDRO-PNEUMATIC – type PA.HSAU

One compact unit is integrated with hydraulic shock absorber and pneumatic cylinder for all the other check valve functions.

HYDRO-MECHANICAL – type MA.HSAU

Consists of two devices, one is a hydraulic shock absorber for damping at closing direction and the second one is an electro-mechanical device powered manually by hand wheel or electrically with an AUMA-like device placed on the other side of the check valve shaft which perfroms all the other check valve functions.

Features of HSAU damping unit:

Innovative and most reliable heavy duty concept

High speed closing of check valves by damping torque transfer without additional bending of valve shafts or additional loading of check valves, such as bearing or similar.

Universality of application, quick and easy installation. The system is based on ISO 5211 , it can be connected directly or by using an intermediate flange.

Two or three hydraulic adjustable damping stages.

Safety system to control torque for protection of damping units and check valves.

Wide range of different damping and control solution based on hydraulic shock absorber design with differential and equal piston area

Wide range of damping torques, 8 standard sizes, applicable to damping torques from 500 to 275.00 NM/damping unit

Selection of damping units according to the conditions of water hammer and back pressure, not according to the size of check vavles.

In tandem execution ( both sides assembly, there is no need for interconnecting shock absorbers through special flexible pipes ).

Simple harmonization with specific customer equirements.

Simple interchangeability of all parts means simple maintenance and long service life even in harshest conditions.

Considering all of the specified factors, HYDROMAT’s damping units are the most competetive ones in terms of price.

Depending on design, they can be mounted on a pipeline in any position or angle.

HYDROMAT’s exceptional product!

Protects the plant against water hammer and contributes to considerable energy savings which in fact equals to financial savings.

Quick and easy “Plug and play” installation on different types of check valves

Mounting system based on iso 5211 flanges

Basic characteristics of combined check valves:

Automatic free-acting of hydraulic damping system in closing direction

Flow control capability together with priorty check valve function

Tight shut-off

Hydraulically maintaining full open position , which means no flow losses

Installation space and cost savings

8 standard sizes, damping torque up to 250000 Nm per unit

COMBINED PROPERTIES OF CHECK VALVES

Tilting check valves with disc and flaps

A conventional check valve doesn’t generally provide flow control capability and its utilized completely for the check function. However, in many applications, the check valve is installed on the piping system with isolating shut-off valve connected in series. The line length between the check valve and an additonal valve that is placed into service requires five times the nominal pipe diameter, which consumes extra weight and lenght as well as it necessitates more supports and hangers. Furthermore, check valve with an additional gate valve requires four flanges, four gaskets and four sets of bolts, while the combined valve represents a combination of both shut-off and check function in one and it only requires two sets of each. Consequently, its reasonable to combine these two valve functions into a single valve.

Combined check valves

In addition to hydraulic damping in the closing direction, these systems have flow control capability in the sense of taking any disc position hydraulically, which includes the check valve throttling position, tight shut-off position and holding the full-open position. These are the main characteristics of combined check valves.

NEW* Hydromat’s solution / Combined check valve

Combined properties of tilting check valve realized with hydraulic automatized damping unit type HA.HSAU

Combined properties of tilting check valve realized with hydraulic automatized damping unit type HA.HSAU