HYDRAULIC SHOCK ABSORBERS – TYPE HSA

MAIN TECHNICAL CHARACTERISTIC OF HYDRAULIC SHOCK ABSORBERS TYPE HSA

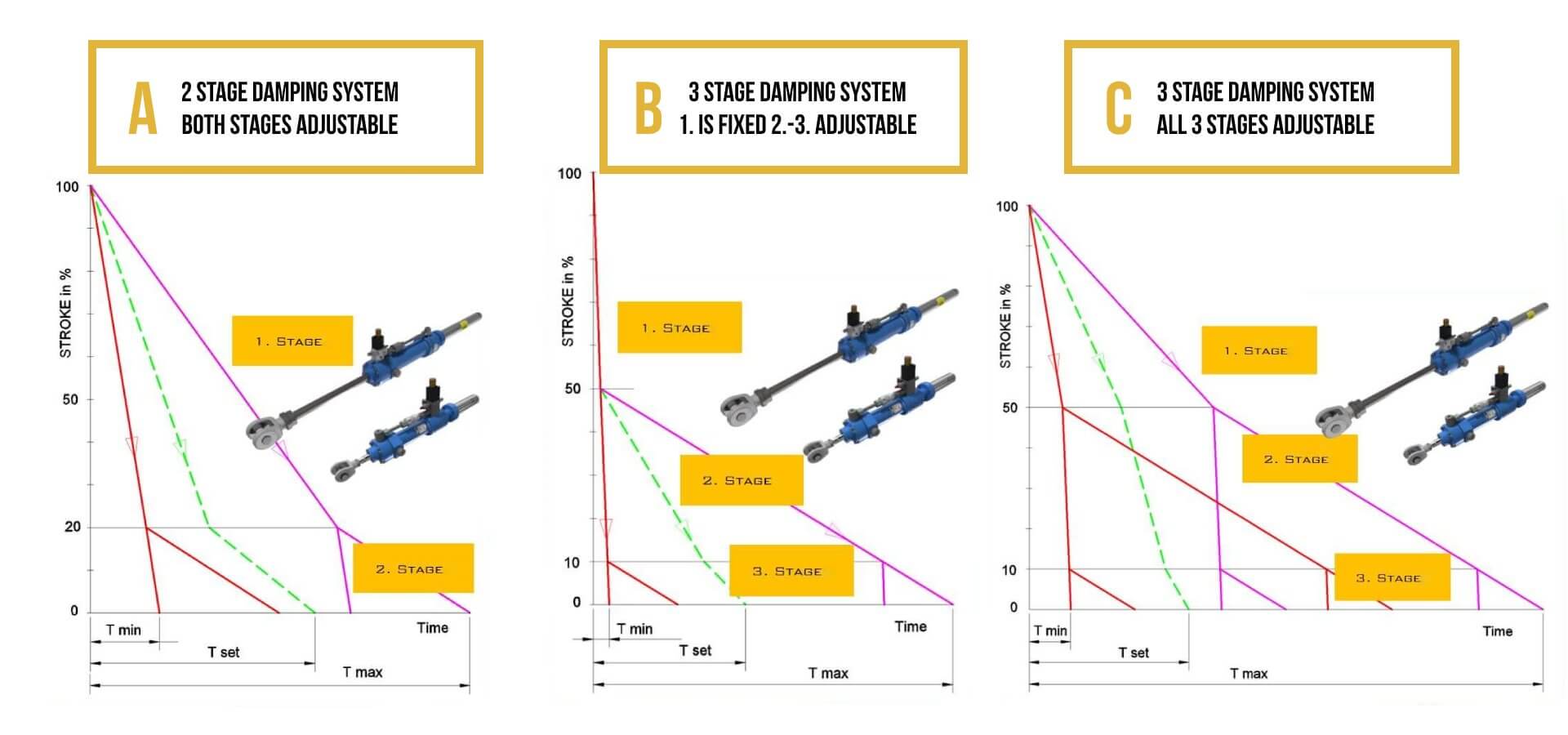

Reliable energy absorbing with two or three adjustable damping stages.

Hydomrat’s performance of main types of hydraulic damping system

A – 2 stage damping:

1. Stage 100 – 20%, Adjustable

2. Stage 20 – 0%, Close, Adjustable

Main characteristic:

For less demanding Applications.

B – 3 stage damping:

1. Stage 100 – 50%, Without adjusting

2. Stage 50 – 10%, Adjustable

3. Stage 10 – 0%, Close, Adjustable

Main characteristic:

Possibility of obtaining extremely high speed check valve closing. Very reliable damping system for demanding application at itensive water hammer.

C – 3 stage damping:

1. Stage 100 – 50%, Adjustable

2. Stage 50 – 10%, Adjustable

3. Stage 10 – 0%, Close, Adjustable

Main characteristic:

Very wide adjustment range, application for demading situations.

Range of ambient temperature, valid for all types:

1. Standard: 30 C to 100 C

2. High: 20 C to 160 C

3. Low: 40 C to 100 C

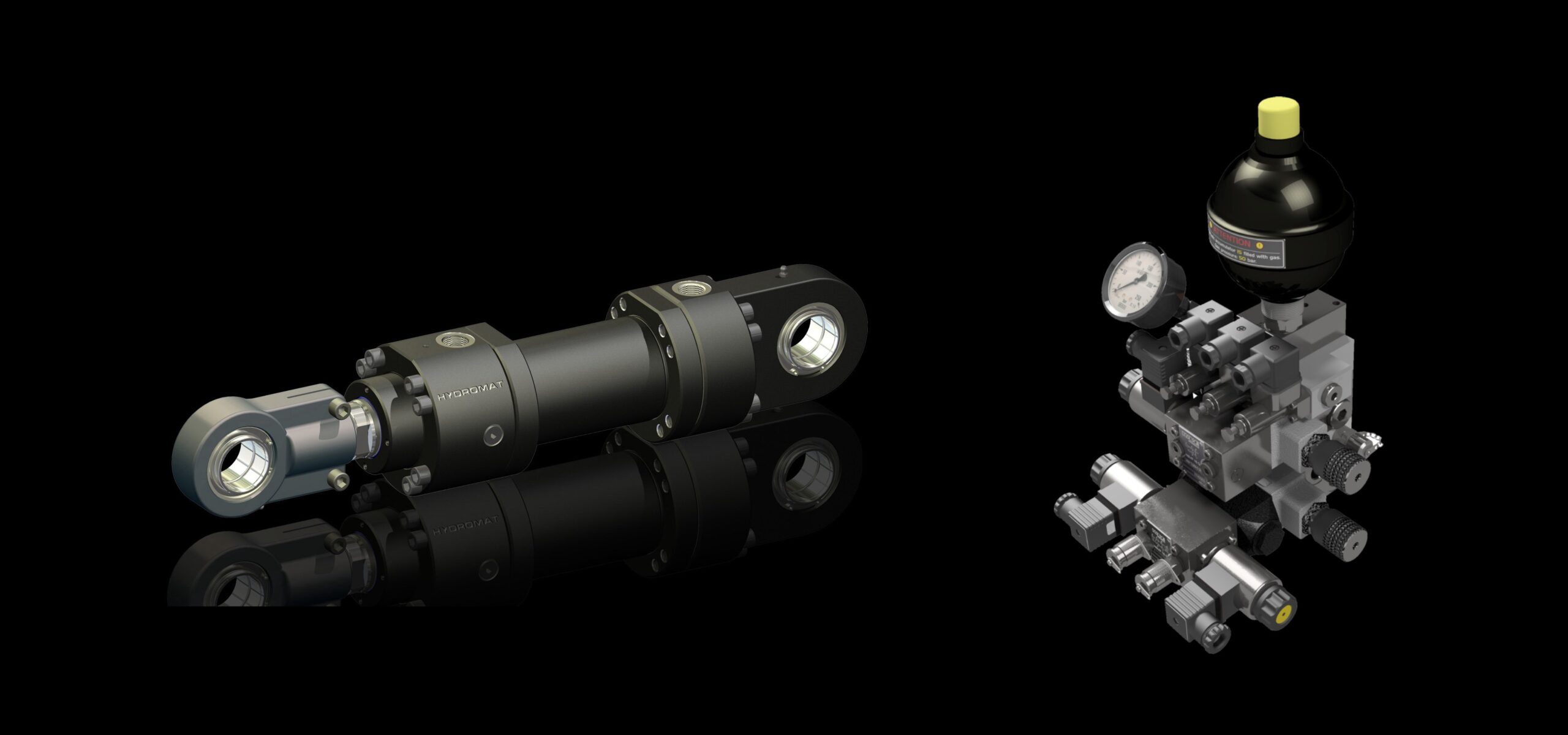

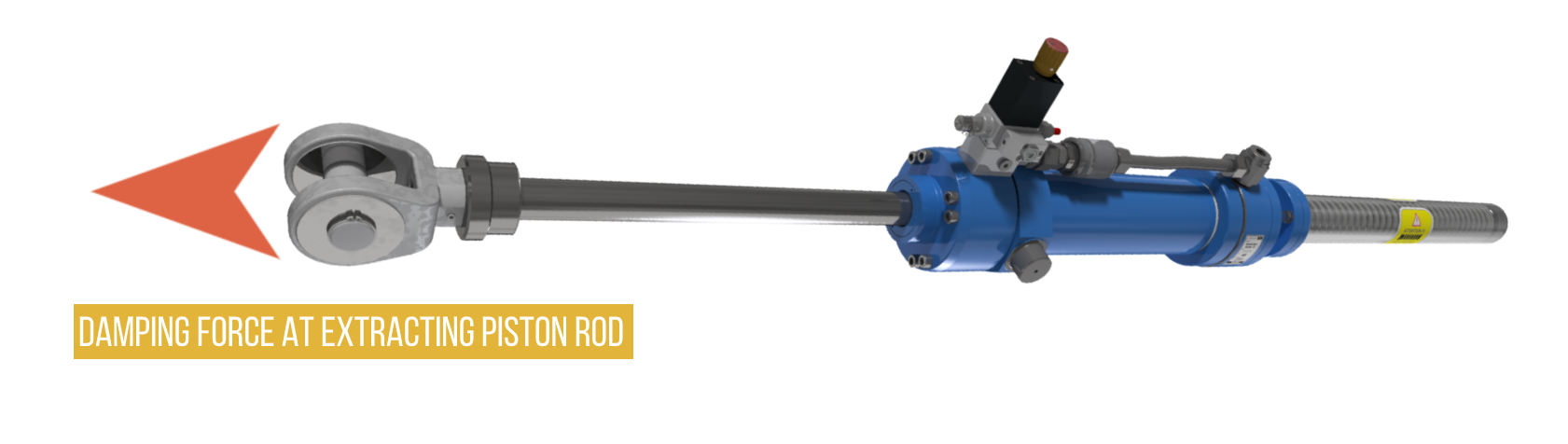

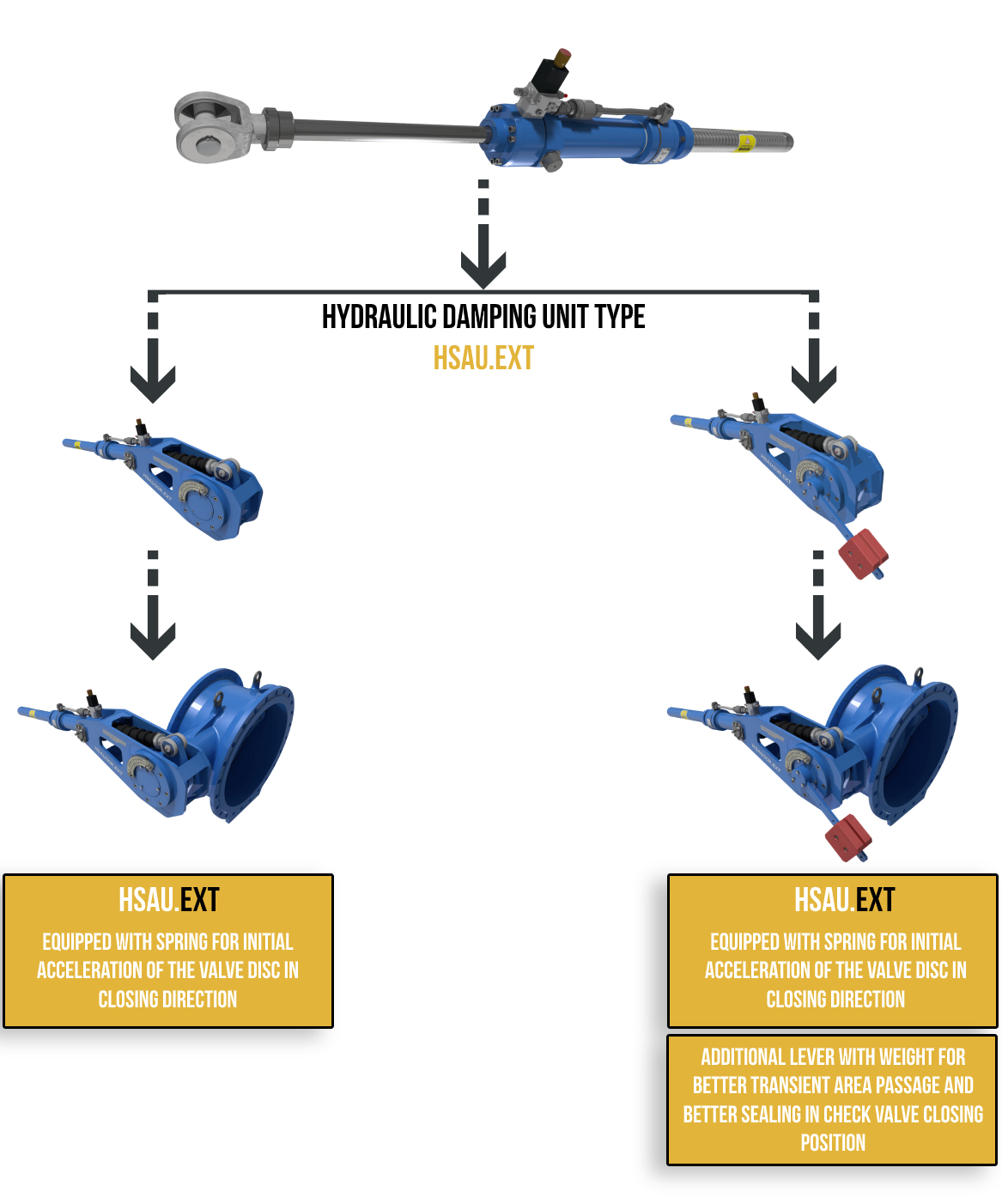

Hydraulic shock absorber type HSA.EXT is the preffered solution. Damping direction at extracting piston rod.

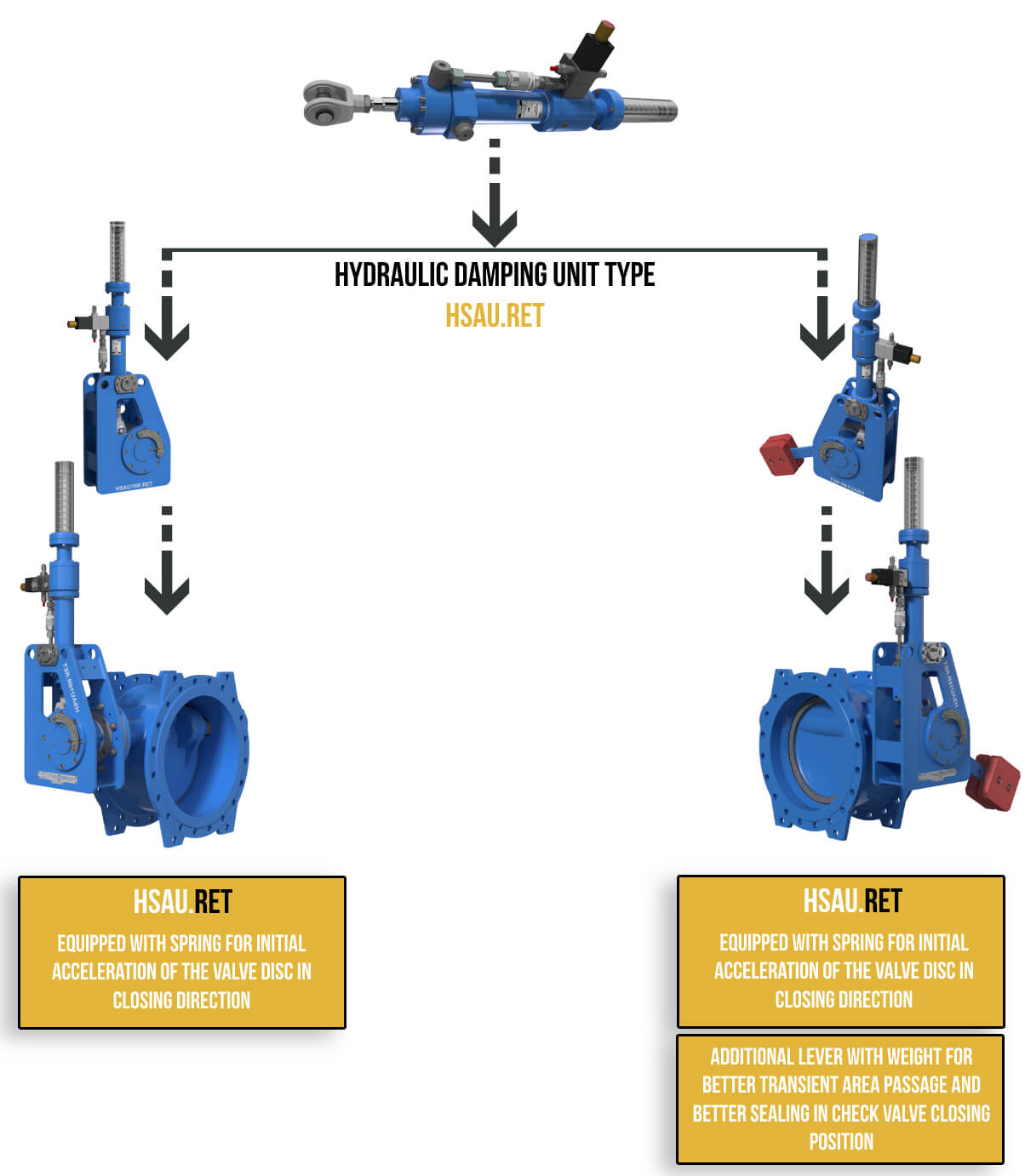

Hydraulic shock absorber type HSA.RET with Damping direction at extracting piston rod.

Compact hydraulic control block and system provides:

Reliable damping control and adjusting

Torque control and system protection against overload

Wide range of possibility to adjusting of damping characteristic with hydraulic throttle or flow control valve

Options, complete hydraulic block and components from stainless steel

Other on request

OPTION: The piston rod made from stainless steel and additional rubber bellow for protection in the hardest working environments

HSA.EXT

HSA.RET

HSA.EXT/MAIN TECHNICAL CHARACTERISTICS

The most reliable hydraulic system to download large amounts of damping energy for high speed check valve closing

The Piston rod is loaded only tensile and the closing damping energy of the check valve has been downloaded on differential area of piston rod side of shock absorber.

The Piston rod is completely protected in the retracted position when the check valve is open, which in fact means all the time when the pump is working. At pump stop or power failure the damping process is started by extracting of the piston rod of shock absorber. This is an important property especially in plants with lot of dust and humidity , marine and off-shore working conditions and generally difficult working conditions of equipment.

All sizes and versions of this type of shock absorbers are additionally fitted with a spring with force adjustment in order to start as quickly as possible in the check valve closing direction.

Hydraulic shock absorber system is designed primary for damping when check valves are closing and if necessary they can be equipped with damping of the last 10% stroke at opening.

Robust, compact and clean design of external surfaces with usage of quality materials, which allow application in the most demanding work environments, including “outdoor” applications.

Mounting in any position and under any inclination on the pipeline.

System design allows for long lasting life of the product with easy and quick replacement of all parts.

Technical characteristics can be aligned with customer requests.

HSA.RET/MAIN TECHNICAL CHARACTERISTICS

Hydraulic system to download required damping energy for reliable closure of the check valve.

The piston rod is under compression load, buckling and the closing damping energy of the check valve, therefore it’s being transferred on the full piston area of the shock absorber.

The piston rod is completely in extracted position when the check valve is open, which in fact means all the time when the pump is working. At pump stops or power failure the damping process is started by retracting the piston rod of shock absorber.

All sizes and versions of this type of shock absorbers are fitted with a spring for force adjustment in order to start as quickly as possible in the check valve closing direction.

Hydraulic shock absorber system is primary designed for damping when the check valves are closing and if necessary they can be equipped with damping of the last 10 % stroke at opening.

Robust, compact and clean design of external surfaces with usage of quality materials, which allows application in the most demanding work environments, including “outdoor” applications.

Mounting in any position and under any inclination on the pipeline.

System design allows for long lasting life of the product with easy and quick replacement of all parts.

On request, the piston rod can be made from stainless steel and additional rubber bellow protection for the hardest working conditions.

Technical characteristics can be aligned with customer requests.